Table Of Content

AMD silicon are the among the most energy efficient compute you can use for the most demanding compute tasks. The high performance of AMD EPYC processors for massive, demanding workloads is one of the key reasons it was selected as the compute engine of the Frontier supercomputer at the U.S. Just as critically, the same Frontier architecture topped the Green500 list of energy efficient systems upon its debut in June 2022.

Software focuses

Most research employs a “black box model,” assuming that a DUT is a black box whose inputs can be controlled and outputs monitored. They employ various ML techniques to learn from historical input/output/observation data to tune the random test generators or eliminate tests that are unlikely to be useful. In a recent development, a reinforcement learning (RL) based model was used to learn from a DUT’s output and predict the most probable tests for a cache controller. An ML architecture with a much finer granularity requires that an ML model be trained for every cover point. A ternary classifier is also employed to help decide if a test shall be simulated, discarded, or used to retrain a model further. Support vector machine (SVM), random forest, and deep neural network are all experimented on a CPU design.

Working at Scale

All the algorithms, including random forest, Support Vector Classification (SVC), decision tree, logistic regression, K-neighbors, and naïve Bayes, are compared on their power to predict root causes. The best score was achieved by random forest with 90.7% prediction accuracy and 0.913 F1 scores. Another approach proposes to use a labeled dataset from code commit to train a gradient boosting model, where more than 100 features about authors, revisions, codes, and projects were tested until 36 were selected for the algorithm. The experiments show that it is possible to predict which commits are most likely to contain buggy code and potentially reduce manual bug-hunting time significantly. Comprehensive portfolio of tools for the design, verification and manufacturing of integrated circuits.

Customer Case Studies with AI/ML in Verification

Alternatively, an event pattern rarely occurs in the traces can be regarded as an anomaly; therefore, it can be used for diagnostic and debugging purposes. Requirement engineering in functional verification is the process of defining, documenting, and maintaining verification requirements, which is critical to ensure the excellent quality of the underlying IC design. EDA 4.0 has evolved to facilitate the design of intelligent and connected devices, harnessing the potential of cloud computing and artificial intelligence (AI) and machine learning (ML) capabilities.

Keysight EDA boosts simulation support for Tower RF ... - eeNews Europe

Keysight EDA boosts simulation support for Tower RF ....

Posted: Thu, 16 Nov 2023 08:00:00 GMT [source]

IC designer uses EDA tools to complete schematic design, layout design, circuit simulation, design verification, chip manufacturing, and packaging testing. The automation and intelligence of EDA tools improve the efficiency and accuracy of IC designs. Simulation EDA tools work to predict a circuit’s behavior before it is developed, effectively modeling how a real version of this circuit would perform.

Industry Sponsors

EDA software allows developers to design, model, simulate, test, and analyze circuit designs to identify potential issues before they enter production. EDA software also includes design reusability features that help simplify the design process. EDA is particularly important for semiconductor design, but it also has significant uses in PCB board design and flat panel display design.

Chinese government support produces 100 domestic EDA vendors, but few will survive - DIGITIMES

Chinese government support produces 100 domestic EDA vendors, but few will survive.

Posted: Thu, 25 Jan 2024 08:00:00 GMT [source]

What is China doing regarding EDA?

Regarding the manufacturing of these devices, the primary providers of this service are semiconductor foundries, or fabs. These highly complex and costly facilities are either owned and operated by large, vertically integrated semiconductor companies or operated as independent, “pure-play” manufacturing service providers. EDA tools are also used for programming design functionality into FPGAs or field-programmable gate arrays, customisable integrated circuit designs. Current digital flows are extremely modular, with front ends producing standardized design descriptions that compile into invocations of units similar to cells without regard to their individual technology. Cells implement logic or other electronic functions via the utilisation of a particular integrated circuit technology.

It provides a platform for packaging design, including package design, verification, implementation, and other connections. It should be mentioned that as chip processes get closer to their physical limits, 2.5D/3D packaging, chipsets, and other forms of advanced packaging are emerging as new ways to enhance chip integration. Additionally, demand for complete IC packages is becoming more and more like the situation during IC design. As a result, chip design is no longer a single-chip issue and gradually transforms into a multi-chip system engineering challenge.

Topics of ML in functional verification

AMD solutions are used across sensors to supercomputers, cameras to climate modeling. Systems powered by AMD EPYC™ CPUs are used in innovative scientific breakthroughs – from simulating the inner structure of atoms, to mapping the edges of our universe. As this kind of information is not yet available, the best they can do is pick the tests that are the most irrelevant to the historical tests. Another promising experiment explored a different approach, where the DUT is regarded as a white box, and the code is analyzed and converted to a Control / Data Flow Graph (CDFG).

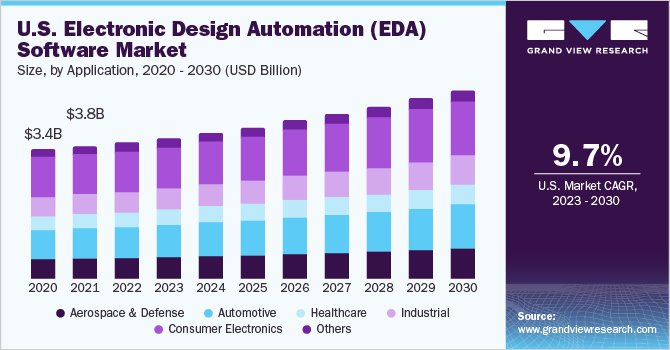

These teams turn to electronic design automation (EDA) software to streamline and automate chip design, predict certain elements of the design process, and test their technology as they develop it. EDA tools take semiconductor chips through their full lifecycle, helping organizations plan, design, build, and validate. Electronic Design Automation (EDA) is a specific category of hardware, software, services and processes that use computer-aided design to develop complex electronic systems like printed circuit boards, integrated circuits and microprocessors. Verification tools examine either the logical or physical representation of the chip to determine if the resultant design is connected correctly and will deliver the required performance. Physical verification examines the interconnected geometries to ensure their placement obeys the manufacturing requirements of the fab. These requirements have become very complex and can include far more than 10,000 rules.

This approach is called equivalence checking and is a part of a discipline known as formal verification. Before the invention of EDA tools, circuit designers drew their designs by hand. Using EDA software, electronic designers can create integrated circuit products from circuit design to performance analysis to design IC layout or PCB layout, substantially increasing work efficiency and lowering labour intensity. This optimises the chip manufacturing process and drives the downstream links of the chip industry chain.

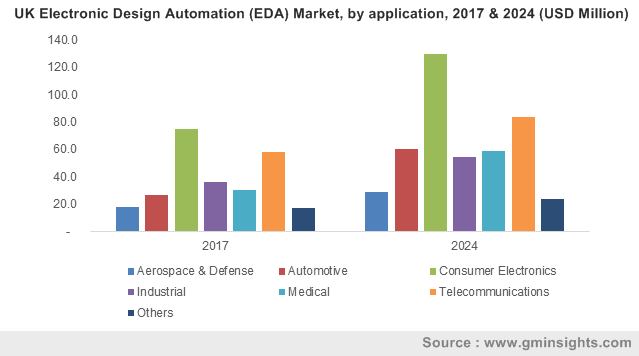

This has caused delays and shortages in essential components and raw materials needed for semiconductor manufacturing, affecting EDA tool utilization. Additionally, the war has created economic uncertainty, potentially leading to project cancellations or deferrals in various sectors that rely on EDA solutions. For example, a slowdown in the automotive sector could lead to decreased demand for semiconductor chips and, subsequently, a reduced need for EDA tools in chip design. The aerospace and defense sector provides significant growth opportunities within the EDA market. Semiconductor chips for these industries require rigorous testing and specialized manufacturing processes to withstand harsh conditions and ensure reliability.

No comments:

Post a Comment